What Is One Part of a Regular Vessel and Engine Maintenance Program?

| Key Takeaway | Description |

|---|---|

| Engine Oil Changes | Regularly changing the engine oil and filter is a critical part of a routine maintenance program |

| Oil Change Intervals | The article recommends changing engine oil and filters every 100 hours of operation or annually |

| Importance of Oil Changes | Proper oil changes help extend engine life by removing contaminants and replenishing lubricating properties |

| Maintenance Schedules | Following the manufacturer's recommended maintenance schedule is important for warranty compliance |

| Visual Inspections | Regular visual checks of the engine, fuel system, and other components can identify potential issues |

| Preventative Maintenance | Proactive maintenance helps avoid breakdowns and ensures the vessel operates safely and reliably |

| Record Keeping | Maintaining detailed maintenance records is essential for warranty claims and resale value |

The key point emphasized in the article is that regular engine oil changes are a critical part of an overall vessel and engine maintenance program. Following the manufacturer's recommended intervals and maintaining detailed records are important for preserving warranty coverage, engine life, and safe/reliable operation.

Vessel and engine maintenance is a critical aspect of ensuring the smooth operation and longevity of marine equipment. By implementing a regular maintenance program, ship owners and operators can minimize downtime, reduce repair costs, and optimize vessel performance. This article explores the importance of regular maintenance and provides insights into the key components of a comprehensive maintenance program.

Understanding Vessel and Engine Maintenance

Regular maintenance plays a vital role in keeping vessels in top condition. It involves a series of scheduled checks, inspections, and tasks aimed at detecting and addressing potential issues before they escalate. The primary goal is to keep both the vessel and its engine in optimal working condition throughout their service life.

When it comes to vessel maintenance, there are several key areas that require attention. One important aspect is the hull of the vessel. Regular inspection and cleaning of the hull are essential to prevent the build-up of marine growth such as barnacles and algae. These organisms can increase drag and reduce fuel efficiency, ultimately affecting the vessel's performance. Additionally, a well-maintained hull helps to prevent corrosion and extend the lifespan of the vessel.

Another crucial component of vessel maintenance is the electrical system. Regular checks and maintenance of the electrical wiring, connections, and components are necessary to ensure safe and reliable operation. Faulty electrical systems can lead to various issues, including power failures, equipment malfunctions, and even fires. Therefore, thorough inspections and necessary repairs or replacements are essential to maintain the integrity of the electrical system.

The Importance of Regular Maintenance

Regular maintenance is crucial for several reasons. Firstly, it improves the safety and reliability of vessels. By performing routine checks, operators can identify and resolve safety hazards, preventing accidents or malfunctions that could endanger crew members and marine environments.

Secondly, regular maintenance helps to prolong the lifespan of vessels and engines. Proper care and upkeep prevent premature wear and degradation of critical components, allowing the vessel to serve its intended purpose for many years. This not only maximizes the return on investment but also promotes sustainability by reducing the need for frequent replacements.

In addition to safety and longevity, regular maintenance also contributes to the overall efficiency of vessels. For example, routine engine maintenance ensures that the engine operates at its peak performance, minimizing fuel consumption and emissions. This not only saves costs but also reduces the environmental impact of vessel operations.

Key Components of a Maintenance Program

A comprehensive maintenance program consists of various essential components. These include safety checks and procedures, cleaning and upkeep, routine inspections, and engine maintenance. Let's delve into each of these aspects in detail to gain a better understanding of their significance.

Safety checks and procedures are fundamental to any maintenance program. This involves inspecting safety equipment such as life jackets, fire extinguishers, and emergency alarms to ensure they are in proper working condition. Regular drills and training sessions are also conducted to familiarize crew members with emergency procedures, enhancing their preparedness in critical situations.

Cleaning and upkeep are crucial to maintaining a clean and organized vessel. Regular cleaning of the interior and exterior surfaces helps to prevent the accumulation of dirt, debris, and contaminants. This not only improves the aesthetics but also prevents potential damage caused by corrosive substances or pests.

Routine inspections are an integral part of any maintenance program. These inspections involve a thorough examination of various components and systems, including but not limited to, the hull, electrical systems, propulsion systems, and navigation equipment. By identifying and addressing any issues early on, operators can prevent costly breakdowns and ensure the vessel's continued operation.

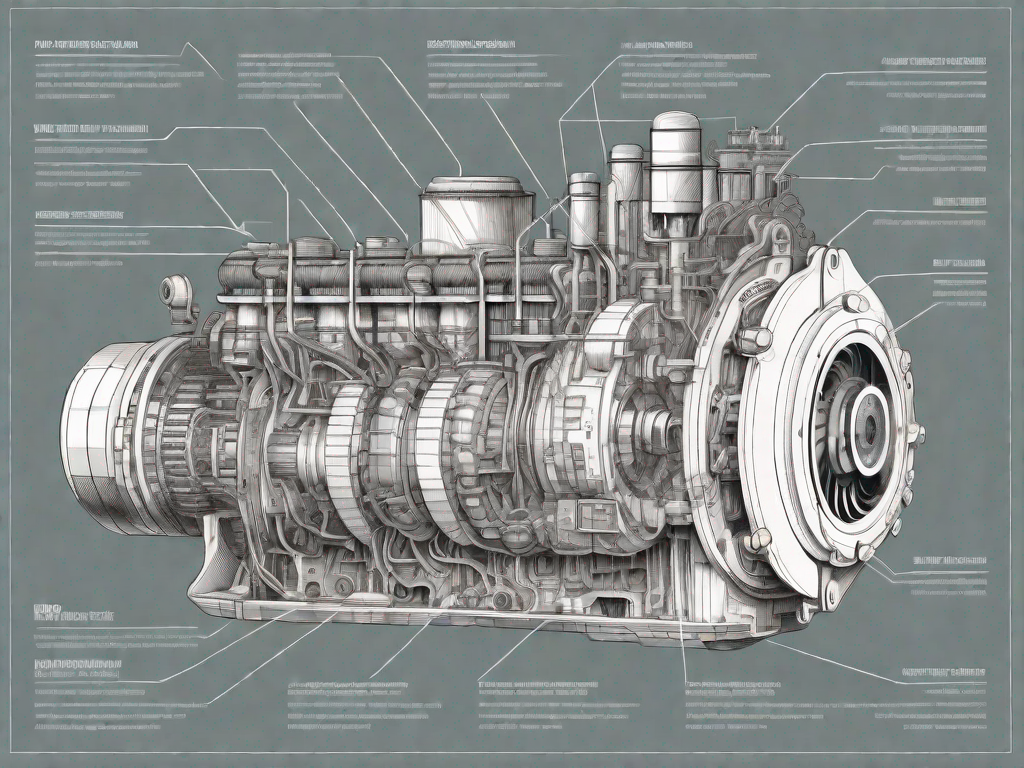

Engine maintenance is a critical aspect of vessel maintenance. This includes regular oil changes, filter replacements, and inspections of various engine components such as belts, hoses, and cooling systems. Proper engine maintenance not only ensures optimal performance but also extends the engine's lifespan, reducing the need for expensive repairs or replacements.

Exploring Different Parts of a Maintenance Program

In order to maintain the safety and efficiency of a vessel, it is essential to implement a comprehensive maintenance program. This program consists of various components that work together to ensure the smooth operation of the vessel. Let's delve deeper into some of the key aspects of a maintenance program:

Safety Checks and Procedures

Prioritizing safety is paramount in any maintenance program. Regular safety checks ensure that all safety equipment, such as fire extinguishers, life rafts, and emergency systems, are in working order. These checks involve inspecting the equipment, testing its functionality, and replacing any faulty or expired items. Additionally, safety procedures, including proper handling of hazardous materials and adherence to established protocols, play a crucial role in preventing accidents and maintaining a safe working environment. These procedures may include training sessions, safety drills, and the use of personal protective equipment.

Furthermore, it is important to regularly review and update safety policies and procedures to reflect any changes in regulations or industry best practices. This ensures that the maintenance program remains up-to-date and continues to prioritize the well-being of the crew and the vessel.

Cleaning and Upkeep

Cleaning and upkeep are important aspects of vessel maintenance. Regularly cleaning the vessel's exterior and interior not only enhances its appearance but also eliminates dirt, grime, and corrosive substances that could cause damage. This involves using appropriate cleaning agents and techniques to remove stubborn stains, rust, and other contaminants.

Moreover, proper upkeep includes regular lubrication, painting, and antifouling to protect against weathering and extend the lifespan of the vessel. Lubrication ensures that moving parts, such as gears and bearings, operate smoothly and efficiently. Painting not only enhances the vessel's aesthetics but also acts as a protective barrier against corrosion and the damaging effects of the environment. Antifouling, on the other hand, prevents the growth of marine organisms on the hull, reducing drag and improving fuel efficiency.

Routine Inspections

Routine inspections are key to identifying potential issues before they become major problems. These inspections involve a thorough examination of critical components such as the hull, propellers, shafts, and electrical systems. Inspectors may use various tools and techniques, including visual inspections, non-destructive testing, and performance monitoring, to assess the condition and performance of these components.

By detecting and addressing any signs of wear, leaks, or other abnormalities early on, operators can prevent costly breakdowns or accidents and ensure uninterrupted operations. In addition, routine inspections provide valuable data that can be used to develop predictive maintenance strategies, allowing for proactive repairs and replacements based on the condition of the equipment.

It is worth noting that maintenance programs should also include regular training and skill development for the crew members responsible for carrying out inspections and maintenance tasks. This ensures that they have the necessary knowledge and expertise to perform their duties effectively and safely.

In conclusion, a well-designed maintenance program encompasses various elements, including safety checks and procedures, cleaning and upkeep, and routine inspections. By implementing and adhering to such a program, vessel operators can enhance safety, prolong the lifespan of the vessel, and optimize its performance.

Focusing on Engine Maintenance

When it comes to maintaining a vessel, one cannot overlook the importance of engine maintenance. The engine serves as the heart of the vessel, powering it through the water and ensuring smooth operation. Therefore, implementing a comprehensive maintenance program that includes regular engine maintenance is crucial for the overall performance and longevity of the vessel.

The Role of Engine Maintenance

Engine maintenance involves a range of tasks that are essential for keeping the engine in optimal condition. One of the primary tasks is performing oil and filter changes. Regularly changing the oil and filters helps remove contaminants and debris that can accumulate over time, ensuring that the engine operates smoothly.

In addition to oil and filter changes, checking fuel and coolant levels is another critical aspect of engine maintenance. Proper fuel and coolant levels are necessary for the engine to function efficiently and prevent overheating. By regularly monitoring and adjusting these levels, operators can prevent potential issues and ensure the engine's longevity.

Inspecting belts and hoses is also a crucial part of engine maintenance. Belts and hoses can wear out over time, leading to potential failures or leaks. By inspecting them regularly, operators can identify any signs of wear and tear and replace them before they cause significant problems.

Furthermore, cleaning or replacing air filters is an essential task in engine maintenance. Air filters prevent dirt and debris from entering the engine, ensuring clean air intake. Over time, these filters can become clogged, reducing airflow and impacting engine performance. By cleaning or replacing them as needed, operators can maintain optimal engine performance.

Proper engine maintenance plays a vital role in preserving its performance, reducing the risk of breakdowns, and extending its operating life. By investing time and effort into regular maintenance, operators can ensure that their vessel's engine operates at its best, providing a reliable and efficient means of propulsion.

Common Engine Maintenance Tasks

While specific engine maintenance tasks may vary depending on the type of propulsion system and engine specifications, there are several common tasks that apply to most engines.

Regular servicing is one of the fundamental tasks in engine maintenance. This involves following manufacturer guidelines and conducting routine inspections and maintenance procedures at recommended intervals. By adhering to these guidelines, operators can identify and address any potential issues before they escalate into major problems.

Valve adjustments are another crucial aspect of engine maintenance. Over time, valves can become misaligned or worn, affecting engine performance. By periodically adjusting the valves, operators can ensure proper sealing and combustion, maximizing engine efficiency.

Fuel injector cleaning is also an essential task in engine maintenance. Fuel injectors can become clogged or dirty, leading to reduced fuel efficiency and engine performance. By cleaning the fuel injectors regularly, operators can maintain optimal fuel delivery and combustion, resulting in improved engine performance.

Monitoring engine performance through diagnostic tests is another common engine maintenance task. Diagnostic tests, such as analyzing engine data and conducting performance evaluations, help operators identify any potential issues or areas for improvement. By regularly monitoring engine performance, operators can make informed decisions regarding maintenance and adjustments to optimize the engine's operation.

By performing these common engine maintenance tasks and following manufacturer guidelines, operators can keep their vessel's engine running at peak efficiency. Regular maintenance not only ensures reliable performance but also helps prevent costly breakdowns and extends the engine's operating life.

The Impact of Regular Maintenance on Vessel Performance

Enhancing Vessel Lifespan

A well-maintained vessel has a longer service life compared to one that receives irregular or insufficient maintenance. The timely detection and resolution of issues prevent them from worsening and causing extensive damage. This results in a vessel that remains operational for an extended period, reducing the need for costly replacements and contributing to a more sustainable maritime industry.

Ensuring Optimal Performance

Regular maintenance not only extends the lifespan of a vessel but also ensures its optimal performance. Well-maintained engines operate more efficiently and consume less fuel, leading to cost savings and reduced environmental impact. Additionally, maintaining proper alignment, cleanliness, and lubrication of critical components contributes to smooth operation, reduced vibrations, and enhanced onboard comfort.

Implementing a Regular Maintenance Program

Steps to Establish a Maintenance Schedule

Implementing a regular maintenance program requires careful planning and organization. The first step is to develop a maintenance schedule that outlines specific tasks, their frequency, and responsible individuals. This schedule should consider manufacturer recommendations, regulatory requirements, and the vessel's operating conditions. Regular reviews and adjustments ensure the program remains effective and adaptable to changing needs.

The Role of Maintenance Logs

Maintenance logs serve as essential documentation of maintenance activities. They record completed tasks, inspection findings, and any repairs or replacements carried out. These records not only facilitate accountability and traceability but also provide valuable references for future maintenance. Furthermore, maintenance logs enable operators to identify recurring issues, adjust maintenance strategies, and demonstrate compliance with industry standards or regulatory bodies.

Training and Skill Development for Maintenance

Ensuring that personnel possess the necessary skills and knowledge to perform maintenance tasks is crucial for an effective program. Adequate training and skill development programs should be implemented to equip maintenance staff with the necessary expertise and keep them informed about best practices, safety protocols, and technological advancements. Continuous learning and professional development contribute to the success of a maintenance program and the overall operation of the vessel.

In conclusion, regular vessel and engine maintenance is an integral part of any maritime operation. By understanding the importance of maintenance, focusing on different aspects such as safety checks, cleaning, inspections, and engine maintenance, and implementing a well-structured program, ship owners and operators can ensure the safety, sustainability, and optimal performance of their vessels for years to come.

![Furuno NavNet TZtouch3 12" MFD w/1kW Dual Channel CHIRP Sounder w/Internal GPS [TZT12F] - Themarineking.com](http://themarineking.com/cdn/shop/files/83515XL_{width}x.jpg?v=1749586645)

![BoatLIFE LifeSeal Sealant Cartridge - Black [1171] - Themarineking.com](http://themarineking.com/cdn/shop/products/70165XL_{width}x.jpg?v=1648680503)

![Sea-Dog Washdown Faucet - Chrome Plated Brass [512220-1] - Themarineking.com](http://themarineking.com/cdn/shop/products/80045XL_{width}x.jpg?v=1648717358)

![Attwood SWIVL-EZE LakeSport 2-3/8" Seat Mount w/Friction Control - Aluminum [818440] - Themarineking.com](http://themarineking.com/cdn/shop/products/89059XL_{width}x.jpg?v=1648755975)

![JENSEN AM/FM Dipole Soft Wire Antenna [8309819] - Themarineking.com](http://themarineking.com/cdn/shop/products/77725XL_{width}x.jpg?v=1648710148)

![Minn Kota Raptor Jack Plate Adapter Bracket - Starboard - 2" Rise - 4" Rise - Black [1810360] - Themarineking](http://themarineking.com/cdn/shop/products/85194XL_{width}x.jpg?v=1648572035)

![Garmin CCU Extension Cable 5M [010-11156-30] - Themarineking.com](http://themarineking.com/cdn/shop/products/39782XL_{width}x.jpg?v=1648603200)

![Minn Kota Riptide Instinct QUEST 90/115 Trolling Motor w/Wireless Remote - 24/36V - 90/115LBS - 72" -White [1358561] - Themarineking.com](http://themarineking.com/cdn/shop/files/99975XL_{width}x.jpg?v=1688164551)

![Whale Orca 2000 GPH Submersible Bilge Pump 12V [BE2002] - Themarineking.com](http://themarineking.com/cdn/shop/products/59568XL_{width}x.jpg?v=1648647004)

![TACO Green Replacement LED f/Rub Rail Lights F38-6602-1, F38-6602-2, F38-6800D F38-6810B [F38-6000-G] - Themarineking.com](http://themarineking.com/cdn/shop/products/89760XL_{width}x.jpg?v=1648759932)

![Mustang Catalyst Flotation Coat - Orange/Black - XL [MC5446-33-XL-206] - Themarineking.com](http://themarineking.com/cdn/shop/products/92971XL_{width}x.jpg?v=1648773907)

![Dometic 974 Portable Toilet w/Mounting Brackets -2.6 Gallon - Grey [301097406] - Themarineking.com](http://themarineking.com/cdn/shop/files/37723XL_{width}x.jpg?v=1730255907)