Understanding the Purpose of a Ventilation System on a Motorized Vessel

A ventilation system plays a crucial role in maintaining a safe and comfortable environment on a motorized vessel. Whether it's a small pleasure boat or a large commercial ship, proper ventilation is essential for the well-being of both passengers and crew. In this article, we will explore the basics of a ventilation system, its components, how it works, and its importance in various aspects of vessel operation. We will also discuss different types of ventilation systems, safety considerations, and some innovative solutions that have emerged in recent years.

The Basics of a Ventilation System

A ventilation system is designed to circulate air within a vessel, replacing stale or polluted air with fresh air from the outside. It helps regulate temperature, removes moisture, and eliminates odors. Additionally, ventilation systems can aid in preventing the buildup of potentially harmful gases, such as carbon monoxide, ensuring the safety of those on board.

Proper ventilation is crucial for maintaining a comfortable and healthy environment on a vessel. Let's explore the components of a ventilation system in more detail to understand how they work together to achieve effective air circulation.

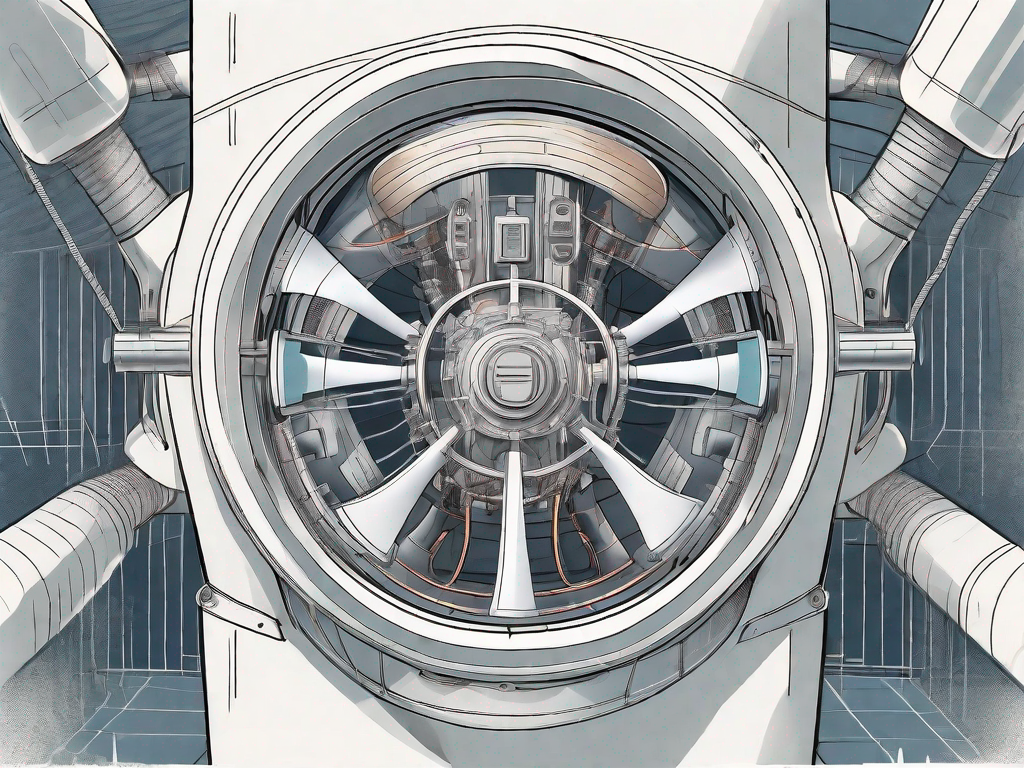

Components of a Ventilation System

1. Ducts: Ducts are the channels through which air travels within the vessel. They can be made of various materials, such as metal or flexible tubing, and are strategically placed to ensure proper air circulation throughout the vessel. The size and design of the ducts are carefully considered to optimize airflow and minimize resistance.

2. Fans or Blowers: Fans or blowers are responsible for moving air through the ductwork. These devices create airflow that helps exchange fresh air with stale air, effectively ventilating the space. The fans or blowers are strategically positioned to maximize air movement and ensure that every corner of the vessel receives proper ventilation.

3. Vents: Vents are openings or outlets that allow air to enter or exit a vessel. They are strategically placed in areas where air circulation is critical, such as engine compartments, cabins, or enclosed spaces. Vents can be equipped with filters to prevent the entry of dust or other particles, ensuring that the circulated air remains clean and fresh.

4. Control Mechanisms: Control mechanisms, such as switches or dampers, allow users to regulate the flow of air within the ventilation system. They enable adjustments to be made based on changing environmental conditions or specific requirements. For example, in colder climates, the control mechanisms can be used to reduce the amount of fresh air intake to maintain a comfortable temperature inside the vessel.

How a Ventilation System Works

The operation of a ventilation system is relatively straightforward. The fans or blowers create airflow, which pulls in fresh air from the outside through the vents. This fresh air displaces the stale air within the vessel, effectively removing any pollutants or contaminants.

As the air circulates, it passes through various areas of the vessel, such as cabins, galleys, or engine rooms. In each space, the air undergoes a process of exchanging heat, moisture, and contaminants with the surrounding environment before eventually exiting the vessel through designated exhaust vents.

Efficient ventilation systems also consider the specific needs of different areas within the vessel. For example, engine rooms require robust ventilation to remove excess heat generated by the machinery, while cabins may require adjustable vents to allow occupants to control the airflow and temperature according to their preferences.

Moreover, ventilation systems can be enhanced with additional features, such as humidity sensors or air quality monitors, to ensure optimal air conditions at all times. These sensors can detect high levels of humidity or pollutants and trigger the ventilation system to adjust accordingly, maintaining a healthy and comfortable environment for everyone on board.

In conclusion, a well-designed ventilation system is essential for maintaining air quality, temperature regulation, and overall comfort on a vessel. By understanding the components and operation of such systems, vessel owners and operators can ensure the well-being and safety of those on board.

Importance of Ventilation in Motorized Vessels

A well-designed ventilation system is crucial for maintaining a safe and comfortable environment on a motorized vessel. Let's explore the key reasons why ventilation is of utmost importance.

Maintaining Air Quality

One of the primary functions of a ventilation system is to maintain good air quality inside the vessel. Adequate ventilation ensures the removal of odors, fumes, and other pollutants, creating a pleasant and healthy environment for those on board.

Without proper ventilation, confined spaces can quickly become stuffy and uncomfortable. Continuous air exchange not only improves comfort but also reduces the likelihood of respiratory issues or other health risks caused by poor air quality.

Imagine being on a motorized vessel, surrounded by the smell of fuel and exhaust fumes. It would be an unpleasant experience, to say the least. However, with a well-designed ventilation system, these odors can be effectively removed, allowing you to enjoy the fresh sea breeze and the smell of the ocean.

Additionally, a ventilation system helps to eliminate the accumulation of moisture, preventing the growth of mold and mildew. This is especially important in areas such as the bilge or engine room, where damp conditions can lead to unpleasant odors and potential damage to the vessel.

Regulating Temperature

Ventilation systems also play a vital role in regulating the temperature inside a motorized vessel. Especially in warmer climates or during hot summer months, excessive heat buildup can make the living or working spaces unbearable.

By exchanging hot air with cooler outside air, ventilation systems help maintain a comfortable temperature, preventing overheating and creating a more pleasant environment for the occupants.

Imagine cruising in tropical waters, where the sun beats down relentlessly. Without proper ventilation, the interior of the vessel would become unbearably hot, making it difficult to relax or carry out any activities. However, with a well-designed ventilation system, the cool breeze from the sea can be channeled into the vessel, providing a refreshing and comfortable atmosphere.

In addition to regulating temperature, ventilation systems also help to reduce humidity levels. High humidity can make the air feel heavy and oppressive, causing discomfort and potentially damaging the vessel's interior. By removing excess moisture, ventilation systems create a more pleasant and dry environment, preventing the formation of condensation on surfaces.

Preventing Condensation and Mold

Proper ventilation is essential for controlling moisture levels within a vessel. Excessive moisture can lead to condensation on surfaces, contributing to the growth of mold and mildew.

Adequate airflow helps to reduce humidity levels and prevent the buildup of moisture, ultimately minimizing the risk of mold growth and associated health problems. This is particularly important in areas such as bathrooms, galleys, or other enclosed spaces where moisture accumulation is more prone to occur.

Imagine waking up in your cozy cabin on a motorized vessel, only to find condensation covering the windows and walls. Not only does this create an unpleasant visual experience, but it also creates a breeding ground for mold and mildew. However, with a well-designed ventilation system, the excess moisture can be effectively removed, keeping your cabin dry and mold-free.

Furthermore, mold and mildew can pose serious health risks, especially for individuals with respiratory conditions or allergies. By maintaining proper ventilation, you can ensure a healthy and safe environment for everyone on board.

Different Types of Ventilation Systems

There are two main types of ventilation systems commonly found in motorized vessels: natural ventilation systems and mechanical ventilation systems.

Natural Ventilation Systems

Natural ventilation systems rely on the natural movement of air to circulate within the vessel. This is achieved through carefully positioned vents or openings that allow outside air to flow in and stagnant air to exit.

While natural ventilation systems may be simpler and cost-effective to install in some cases, they are highly dependent on external factors, such as wind direction and vessel movement. Therefore, they may not provide consistent airflow or be suitable for vessels operating in certain environments or conditions.

Mechanical Ventilation Systems

Mechanical ventilation systems, on the other hand, utilize fans or blowers to create airflow within the vessel. These systems are more reliable and can provide consistent air exchange regardless of external factors.

While mechanical ventilation systems may require more complex installations and associated costs, they offer greater control over air movement and can be tailored to specific vessel requirements.

Safety Considerations for Vessel Ventilation

When it comes to vessel ventilation, safety should always be a top priority. Proper ventilation not only ensures a comfortable and healthy environment but also plays a crucial role in fire safety and overall vessel operation. Let's explore some key safety considerations below.

Ventilation and Fire Safety

Ventilation systems are closely tied to fire safety on motorized vessels. In the event of a fire, properly designed ventilation systems can help limit the spread of smoke and toxic gases, allowing occupants more time to evacuate safely.

It is essential to ensure that ventilation systems are designed to comply with relevant fire safety regulations and that they include features such as fire dampers, smoke detectors, and emergency shutdown controls.

Proper Maintenance of Ventilation Systems

To ensure the continued effectiveness and safety of ventilation systems, regular maintenance is crucial. Routine inspections, cleaning, and servicing of components are necessary to identify and address any potential issues.

Engaging qualified professionals to perform maintenance tasks and adhering to recommended maintenance schedules are essential practices for extending the lifespan of ventilation systems and minimizing the risk of malfunctions or failures.

Innovations in Vessel Ventilation Systems

Vessel ventilation systems have evolved over time, incorporating innovative technologies and design features to enhance efficiency and performance. Let's explore some notable innovations in this field.

Energy-Efficient Ventilation Systems

As sustainability becomes increasingly important across industries, vessel ventilation systems have also embraced energy-efficient technologies. These systems are designed to reduce energy consumption while maintaining optimal air quality and comfort.

Features such as variable speed motors, energy recovery systems, and intelligent sensors are integrated into modern ventilation systems to ensure optimal efficiency and minimize environmental impact.

Smart Ventilation Systems

Advancements in automation and connectivity have paved the way for smart ventilation systems on motorized vessels. These systems utilize sensors, data analytics, and intelligent controls to optimize air exchange based on real-time conditions.

Smart ventilation systems offer the ability to adapt to changing environmental conditions, adjust airflow based on occupancy levels, and even provide remote monitoring and control capabilities. These features enhance convenience, energy efficiency, and overall effectiveness of ventilation systems on board.

Conclusion

Understanding the purpose and functioning of a ventilation system is fundamental for anyone operating or occupying a motorized vessel. Ventilation systems not only contribute to maintaining a safe and comfortable environment but also play a crucial role in ensuring air quality, regulating temperature, and preventing moisture-related issues. By recognizing the importance of different ventilation system components, safety considerations, and innovations in the field, vessel operators and passengers can make informed decisions to ensure the well-being and efficiency of their vessels.