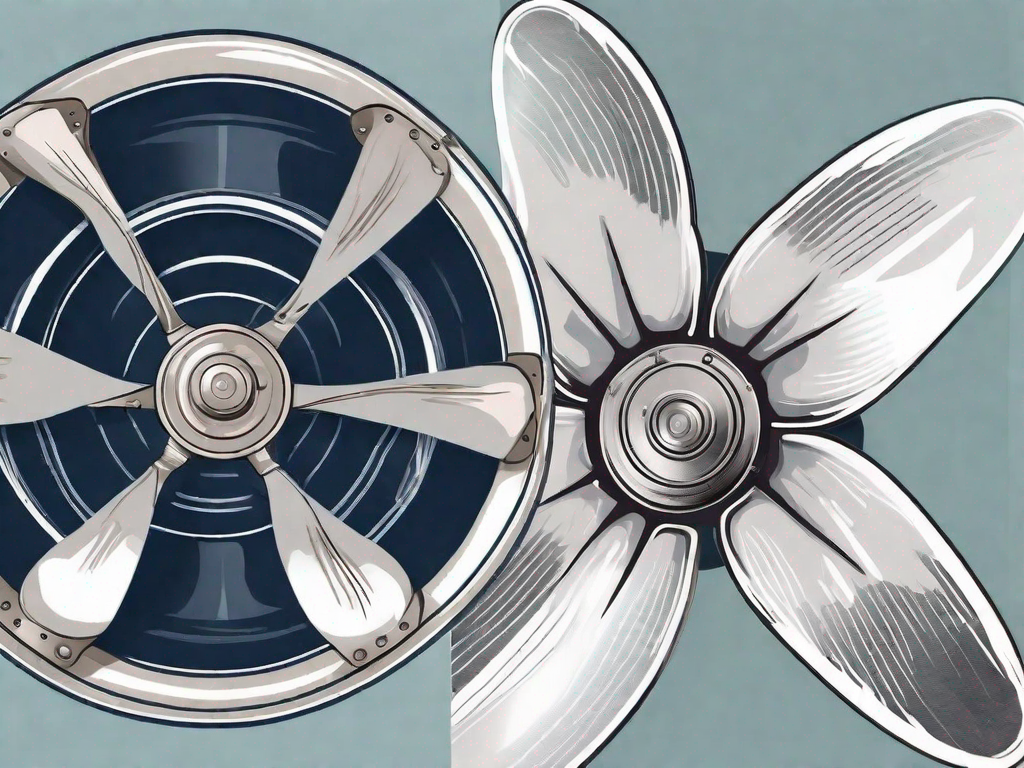

Comparing Stainless Steel and Aluminum Propellers

Propellers play a crucial role in the navigation of maritime vessels, determining their efficiency, speed, and overall performance. When it comes to choosing the right type of propeller, two popular options often come into consideration: stainless steel and aluminum. In this article, we will delve into the characteristics of both stainless steel and aluminum propellers, explore their advantages and potential limitations, and ultimately compare their performance in terms of durability, efficiency, and cost.

Understanding Propellers: An Overview

Before we dive into the specifics of stainless steel and aluminum propellers, let's first gain a general understanding of their role in maritime navigation. Propellers serve to convert the rotational power generated by the vessel's engine into forward thrust, propelling the vessel through the water. The design and composition of the propeller play a pivotal role in determining its efficiency and performance.

The Role of Propellers in Maritime Navigation

Propellers are responsible for providing the necessary propulsion force to move a vessel through water. Their design consists of several key components, each contributing to the overall functionality of the propeller.

When a vessel's engine generates rotational power, it is the propeller's job to convert this power into forward thrust. This thrust is what propels the vessel through the water, allowing it to navigate and reach its destination. Without propellers, maritime navigation as we know it would not be possible.

Propellers are specifically designed to create lift as they rotate. This lift is generated by the blades of the propeller, which are carefully shaped and positioned to maximize efficiency. The angle and curvature of the blades are crucial in determining the amount of lift generated, and thus the amount of forward thrust produced.

In addition to the blades, propellers also consist of a hub and a shaft. The hub serves as the central connecting point for the blades, ensuring that they are securely attached and able to rotate together. The shaft, on the other hand, is responsible for transferring the rotational power from the vessel's engine to the propeller. It acts as the intermediary between the engine and the blades, allowing for the efficient transfer of power.

These key components of a propeller work in harmony to propel the vessel through the water. The blades create lift, the hub connects the blades to the shaft, and the shaft transfers the rotational power from the engine. It is this seamless integration of components that allows propellers to efficiently convert rotational power into forward thrust.

Key Components of a Propeller

A propeller typically consists of blades, a hub, and a shaft. The blades create lift as they rotate, generating forward thrust. The hub connects the blades to the shaft, which transfers the rotational power from the vessel's engine. These components work in harmony to propel the vessel through the water.

The blades of a propeller are carefully designed to maximize efficiency and performance. They are shaped and positioned in a way that allows them to generate lift as they rotate. The angle and curvature of the blades play a crucial role in determining the amount of lift generated, and thus the overall efficiency of the propeller.

The hub of a propeller serves as the central connecting point for the blades. It ensures that the blades are securely attached and able to rotate together. The hub is designed to withstand the forces exerted on the propeller during operation, ensuring that it remains intact and functional even under high loads.

The shaft of a propeller is responsible for transferring the rotational power from the vessel's engine to the propeller. It acts as the intermediary between the engine and the blades, allowing for the efficient transfer of power. The shaft is carefully engineered to withstand the torque and rotational forces exerted on it, ensuring that it remains strong and reliable.

Together, these key components of a propeller work in unison to propel the vessel through the water. The blades create lift, the hub connects the blades to the shaft, and the shaft transfers the rotational power from the engine. It is the careful design and integration of these components that determine the efficiency and performance of a propeller.

Delving into Stainless Steel Propellers

Stainless steel propellers are highly regarded for their robustness and durability. They are commonly used in applications where strength and resistance to corrosion are paramount.

When it comes to propellers, the choice of material is crucial. Stainless steel, an alloy composed mainly of iron, chromium, and nickel, is the preferred material for many propeller manufacturers. This composition gives stainless steel propellers exceptional resistance to corrosion, making them ideal for use in saltwater environments. The presence of chromium in the alloy forms a protective layer on the surface of the propeller, preventing rust and corrosion from taking hold.

But corrosion resistance is not the only advantage of stainless steel propellers. They also offer excellent tensile strength, allowing them to withstand high rotational speeds and heavy loads. This means that even in demanding conditions, such as when a boat is carrying a heavy load or navigating through rough waters, stainless steel propellers can maintain their performance and reliability.

Advantages of Stainless Steel Propellers

One of the key advantages of stainless steel propellers is their durability. They can withstand the harsh conditions often encountered in marine environments, including impacts with underwater debris and continuous exposure to saltwater. Unlike other materials, stainless steel propellers do not easily chip or break, ensuring that they can withstand the rigors of marine life.

Furthermore, stainless steel propellers are renowned for their high efficiency. Their design allows for optimal thrust generation, resulting in improved vessel acceleration and maneuverability. These propellers are particularly well-suited for vessels requiring high performance, such as speedboats and racing yachts. With stainless steel propellers, boat owners can experience enhanced speed and control, making their time on the water even more exhilarating.

Potential Drawbacks of Stainless Steel Propellers

While stainless steel propellers offer numerous advantages, it is important to consider their potential drawbacks as well. One such limitation is their weight. Stainless steel is a denser material compared to aluminum, which can result in increased fuel consumption and reduced vessel speed. The added weight of stainless steel propellers can put a strain on the boat's engine, leading to higher fuel costs and slower speeds.

Additionally, stainless steel propellers tend to be more expensive than their aluminum counterparts. The higher cost is due to the manufacturing process and the quality of the material used. However, many boat owners consider the investment in stainless steel propellers worthwhile, as they offer long-term durability and performance.

In conclusion, stainless steel propellers are a popular choice for boat owners who prioritize strength, durability, and corrosion resistance. Their composition and characteristics make them well-suited for saltwater environments, where other materials may fail. While they may have some drawbacks, such as weight and cost, the benefits of stainless steel propellers often outweigh these considerations. Whether you're cruising through calm waters or racing against the wind, stainless steel propellers can provide the reliability and performance you need.

Exploring Aluminum Propellers

Aluminum propellers are widely used in various marine applications due to their lightweight nature and cost-effectiveness. These propellers are typically crafted from a high-strength aluminum alloy, which offers excellent corrosion resistance, making it suitable for saltwater environments. Moreover, aluminum propellers are significantly lighter than stainless steel propellers, resulting in improved fuel efficiency and increased vessel speed.

Composition and Characteristics of Aluminum

Aluminum propellers are typically crafted from a high-strength aluminum alloy. This alloy is carefully chosen for its specific composition, which includes elements such as copper, manganese, and magnesium. The addition of these elements enhances the strength and durability of the propeller, allowing it to withstand the harsh conditions of marine environments.

Furthermore, aluminum is known for its excellent corrosion resistance. When exposed to saltwater, aluminum forms a protective oxide layer on its surface, preventing further corrosion and ensuring the longevity of the propeller. This corrosion resistance is a crucial factor in the selection of aluminum propellers for saltwater applications.

Benefits of Aluminum Propellers

One of the key advantages of aluminum propellers is their affordability. These propellers are generally less expensive than stainless steel propellers, making them a popular choice among boat owners. The lower cost of aluminum propellers allows boat owners to enjoy the benefits of a high-performance propeller without breaking the bank.

Additionally, the lightweight construction of aluminum propellers offers several benefits. The reduced weight allows for improved acceleration and responsiveness, enhancing the overall performance of the vessel. This increased maneuverability can be particularly advantageous in situations that require quick and precise movements, such as navigating through narrow channels or avoiding obstacles.

Potential Limitations of Aluminum Propellers

Despite their advantages, aluminum propellers have certain limitations. Their lighter construction can make them more susceptible to damage, especially in situations involving impacts with underwater obstacles. However, advancements in alloy composition and design have significantly improved their durability and resistance to deformation.

Modern aluminum propellers are engineered to withstand the rigors of marine environments. They undergo rigorous testing and quality control measures to ensure their strength and durability. Additionally, manufacturers often incorporate advanced design features, such as blade reinforcements and anti-cavitation edges, to further enhance the propeller's performance and longevity.

It is worth noting that aluminum propellers may not be suitable for all types of vessels and applications. In high-performance boats or those with heavy loads, stainless steel propellers may be a more suitable choice due to their increased strength and resistance to deformation. However, for the majority of recreational boaters, aluminum propellers provide an excellent balance of performance, affordability, and durability.

Performance Comparison: Stainless Steel vs Aluminum Propellers

When it comes to comparing stainless steel and aluminum propellers, several factors come into play, including durability, efficiency, and cost.

Durability and Longevity

Stainless steel propellers hold a notable advantage in terms of durability. Their robust construction allows them to withstand harsh conditions and remain resistant to corrosion over extended periods. Aluminum propellers, although lighter and more affordable, may be more prone to damage and deformation.

Efficiency and Speed

When it comes to efficiency and speed, stainless steel propellers offer superior performance. Their design and strength enable them to generate more thrust, resulting in improved acceleration and maneuverability. Aluminum propellers, on the other hand, excel in fuel efficiency due to their lighter weight, but may not achieve the same level of speed as stainless steel propellers.

Cost Analysis

Cost is another factor that plays a role in the choice between stainless steel and aluminum propellers. Stainless steel propellers tend to have a higher initial cost, but their durability and longevity may result in long-term savings. Aluminum propellers, while more affordable upfront, may require more frequent replacement due to potential damage or wear over time.

Ultimately, the choice between stainless steel and aluminum propellers depends on various factors, including the intended use of the vessel, budget considerations, and the desired balance between durability and performance. It is advisable to consult with industry professionals and consider the specific requirements of your vessel before making a decision.

In conclusion, stainless steel and aluminum propellers each offer their own set of advantages and potential limitations. Understanding the composition, characteristics, and performance of both propeller types is crucial in selecting the best option for your marine vessel. Whether you prioritize durability, efficiency, or cost-effectiveness, make an informed decision that aligns with your specific needs and preferences.

![Siren Marine Battery Sensor f/Siren 3 [SM-WLS3-BATT-917] - Themarineking.com](http://themarineking.com/cdn/shop/products/85429XL_{width}x.jpg?v=1648740446)

![Minn Kota Raptor Jack Plate Adapter - Starboard - 2" Setback - 6" Rise - Black [1810362] - Themarineking](http://themarineking.com/cdn/shop/products/85198XL_{width}x.jpg?v=1648572090)